Adapted from the ‘Hydrogen for heating?’ article by David Cebon – Director of the Centre for Sustainable Road Freight and the Cambridge Vehicle Dynamics Consortium; Professor of Mechanical Engineering, University of Cambridge

This two-part article covers the most frequently proposed ways to heat buildings in a low-carbon future. It compares the use of ‘green’ and ‘blue’ hydrogen to power hot water boilers with using electricity to power heat pumps.

In Part 1 the focus of the comparison was on energy efficiency and carbon emissions. Here, the article continues by looking at technology readiness and infrastructure requirements.

Technology readiness

Green hydrogen vs heat pumps

Green hydrogen is produced using renewable energy via electrolysis (for more, visit our data page), but the technology for large-scale electrolysis is not well developed. The largest electrolyser in the world, currently being built by Cummins/Hydrogenics in Canada, has a capacity of 20 MW.

For perspective, approximately 7,500 of these plants would be needed by 2040 to generate the 150 GW of green hydrogen needed to heat the UK’s buildings alone. Unless there is a major development in the technology, it seems unlikely that the installed capacity of electrolysis plants could reach the scale necessary by 2040.

By comparison, heat pumps are standard, mature, off-the shelf technology that can be purchased now. The International Institute of Refrigeration estimates that there are 220 million heat pumps now in use around the world.

Heat pumps do require minor modifications to existing heating systems in buildings, and are currently more expensive than gas boilers (though the prices are expected to drop as demand increases). But these disadvantages of heat pumps pale into insignificance compared with the magnitude of the task of generating sufficient electricity for heating with green hydrogen. Most importantly, the energy cost of heating with a green hydrogen boiler is approximately six times the energy cost of heating with a heat pump (see discussion in Part 1). So the capital cost advantage of a hydrogen boiler will be rapidly overtaken by the much lower operating cost of a heat pump, giving a reasonably short payback period.

Infrastructure requirements

Blue hydrogen vs natural gas-fired boilers

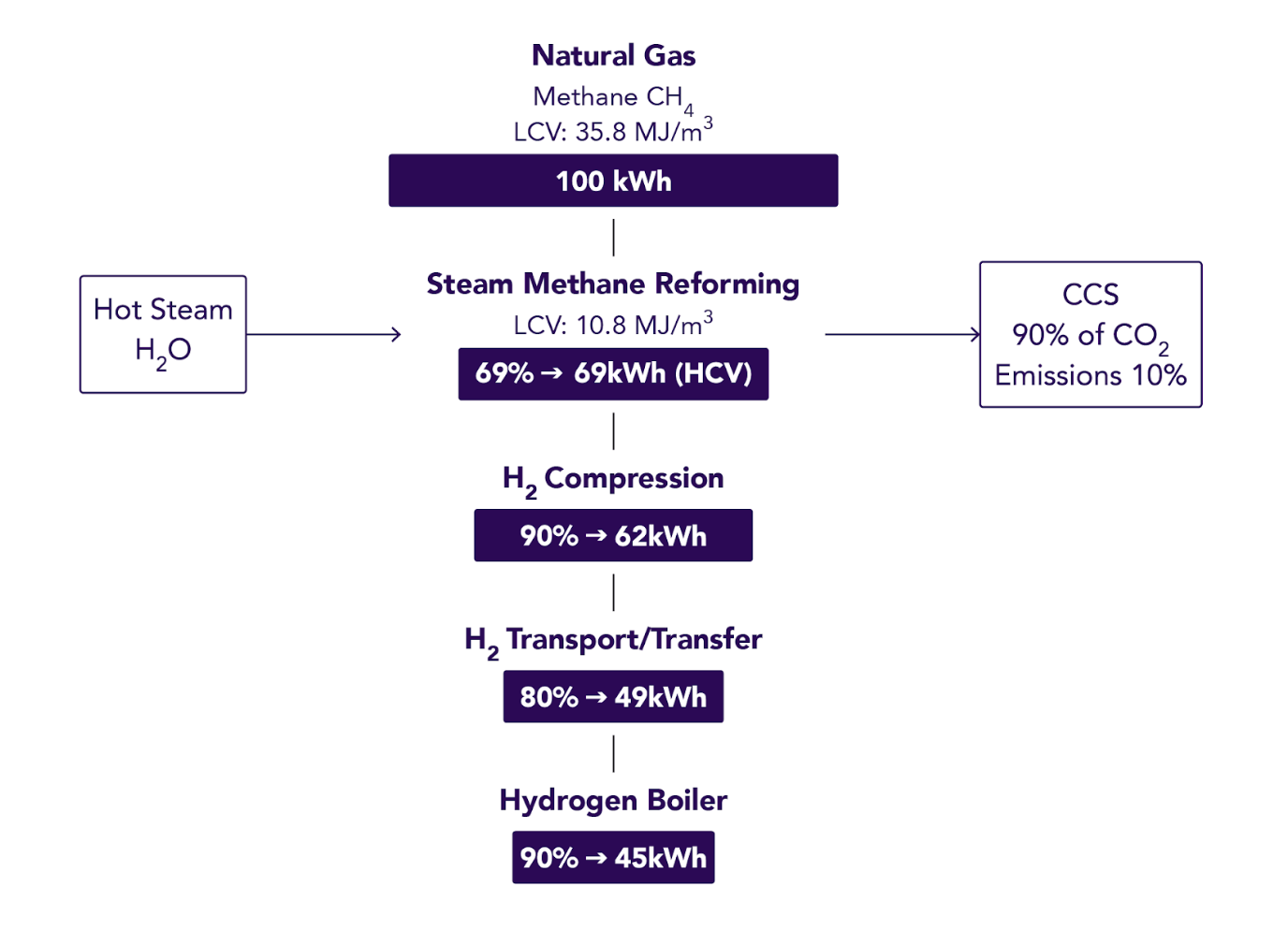

An alternative way to manufacture hydrogen uses the steam methane reforming (SMR) process to produce hydrogen and CO2 from natural gas treated with hot steam. When the CO2 is released into the atmosphere, the resulting hydrogen is called ‘grey’. When the CO2 is captured and stored, the hydrogen is called ‘blue’. The process is shown in Figure 1.

It has been argued that blue hydrogen could replace natural gas for heating as well as transport in a hydrogen economy. The concept is that blue hydrogen would be compressed and pumped through the existing gas transmission network to consumers for use in domestic hydrogen-ready condensing boilers.

However, hydrogen has a significantly lower energy content per unit volume than natural gas (see Figure 1). This means that it is not simply a matter of switching the type of gas in order to deliver the same amount of energy to consumers. Transferring the same amount of energy for heating as existing natural gas distribution would require 35.8/10.8 =3.3 times the volume flow rate of hydrogen. This would only be possible by replacing all of the compressors/pumping stations in the gas network with hydrogen-compatible versions that have about three times the power consumption.

Much of the gas pipeline network would also have to be replaced to make it compatible with hydrogen – preventing leakage and embrittlement. (This problem is recognised by the H21 project in the North of England, which includes extensive plans to install a new mains network.)

It would also be necessary to build the required plant to generate blue hydrogen. Currently there is no commercial-scale CCS facility in the UK for sequestering the CO2 from blue hydrogen production. It would have to be developed and built before any blue hydrogen could be generated.

For context, the international database of CCS facilities shows there are 25 ‘commercial’ CCS facilities operational in the world today, most of which are small-scale. The only commercially viable blue hydrogen facilities pump the CO2 into depleted oil wells for ‘enhanced oil recovery’. This substantially increases the net CO2 emissions when the recovered oil is burned. The CCS industry would have to grow massively to make a significant impact on global CO2 emissions from its grey hydrogen production, and this is very unlikely to occur while there are unfavourable financial conditions for CCS development.

Overall, the infrastructure requirements of blue hydrogen are significant, costly and impactful, while the technology readiness is significantly lacking for implementation in time to meet the 1.5°C or even the 2.0°C global warming targets.

Blue hydrogen and natural gas consumption

In addition to the above, substantially more natural gas would need to be imported or fracked to supply the necessary blue hydrogen for the UK to heat its homes.

For each 100 kWh of ‘input’ natural gas, 45 kWh of heat is delivered via blue hydrogen (see Figure 1). When directly using natural gas for heating (without the SMR step), approximately 65 kWh of heat reaches the consumer for each 100 kWh of natural gas. (This accounts for compression and transport losses and the inefficiency of condensing boilers). Consequently, the blue hydrogen route requires approximately 45% more input natural gas than direct gas heating.

In other words, the UK would consume 45% more natural gas for heating than currently if the energy was delivered via blue hydrogen instead of natural gas.

Figure 1: Blue hydrogen generation using the SMR process with CCS. Data from Bossel, 2006.

Since the UK uses 300 TWh of natural gas per year for domestic purposes, this 45% translates to an additional 135 TWh of natural gas. This would increase gas imports by 25% to 655 TWh and would require 60% of the UK’s natural gas to be imported – severely impacting the nation’s energy security.

In fact, National Grid’s future energy scenario sees the UK importing 100% of gas by 2040, due to depleting North Sea reserves. So the additional gas consumption for blue hydrogen would make the UK’s energy security considerably worse.

Conclusions

- Burning hydrogen is very inefficient compared with the alternative of using a heat pump.

- Hydrogen is wasteful of renewable electricity and/or would substantially increase the amount of natural gas used in the UK.

- Emissions from burning blue or green hydrogen are significantly higher than those of heat pumps.

- It is unlikely the infrastructure for a blue or green hydrogen economy could be built by 2040.

Hydrogen is a fundamentally poor choice for heating buildings and should not be on the policy agenda. Heat pumps and energy efficiency should be government policy instead.